Overview

Let’s talk about a problem that doesn’t get enough attention (source: I have asthma and wear glasses).

For people who are both visually impaired and living with asthma, tracking medication usage through an inhaler can be frustrating. Most commercial inhalers rely entirely on visual counters or a tiny number printed on the top to tell you how many doses a canister has. In my opinion, that’s not inclusive design.

So, our team set out to change that.

Our Solution

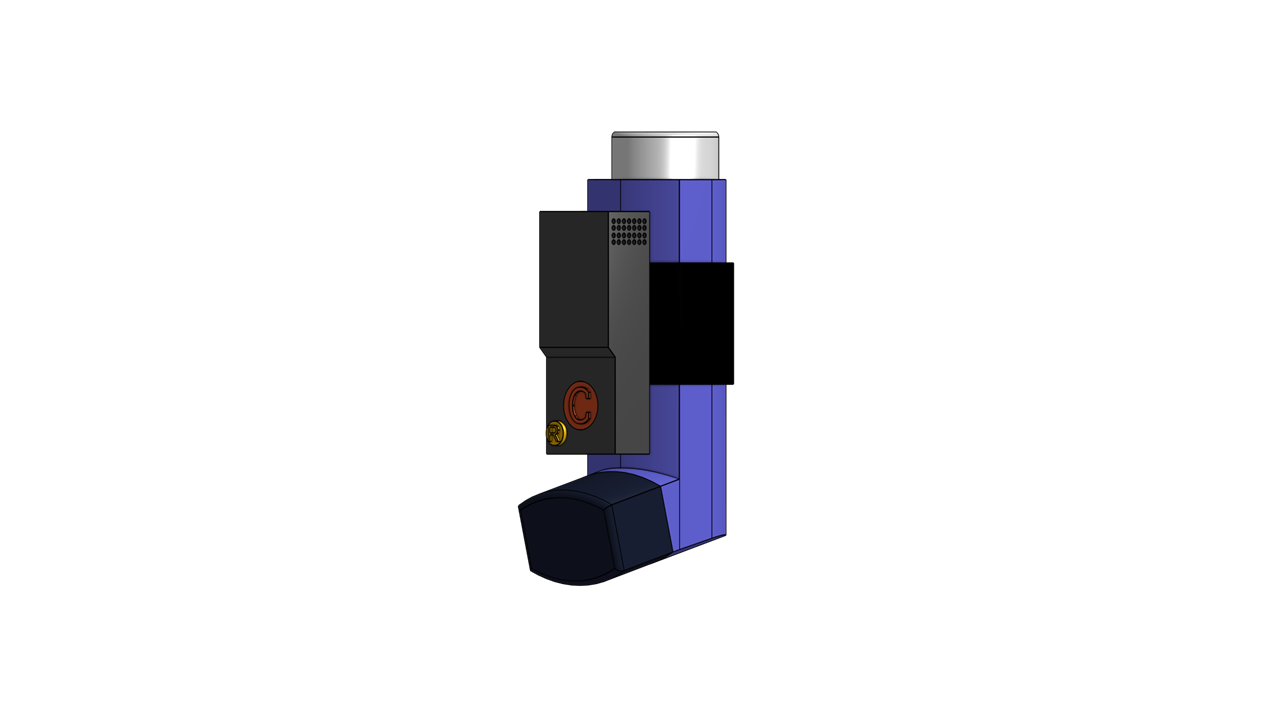

We designed a non-visual inhaler counter that fits onto an existing inhaler and tells users how much medication they have left. But instead of using a screen, it uses beeps and vibrations to communicate dosage levels. Think of it like a car key fob: compact, tactile, and discreet. We wanted the user to get the information they needed, quickly and clearly, without ever needing to look at the device.

Figure 1: Inhaler Counter Model Comparison to Car Key Fob

Figure 1: Inhaler Counter Model Comparison to Car Key Fob

How It Works

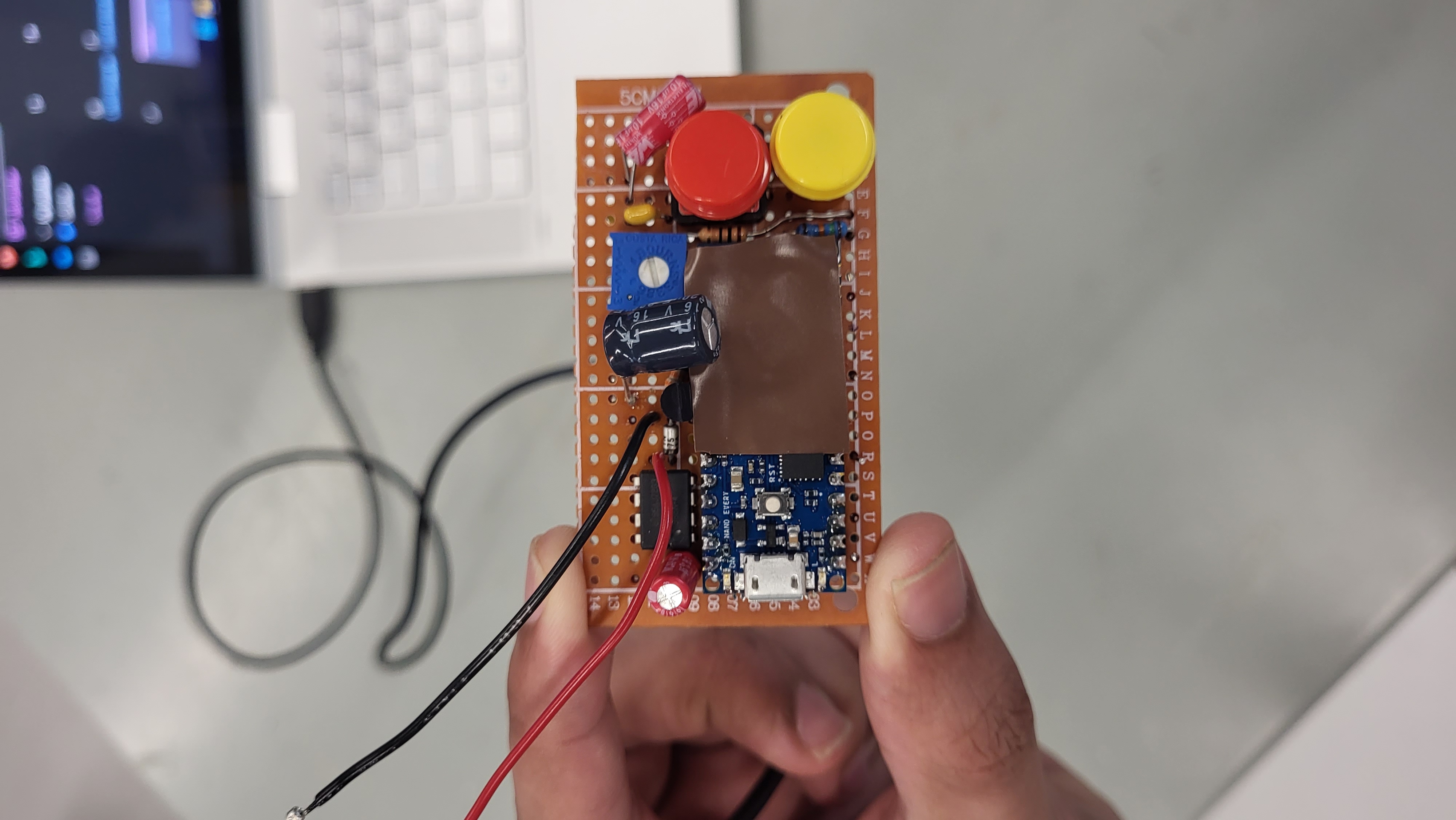

The inhaler counter runs on an Arduino Nano and includes:

- Arduino Nano

- Piezo buzzer & speaker

- Two tactile buttons

- 3D-printed PLA case

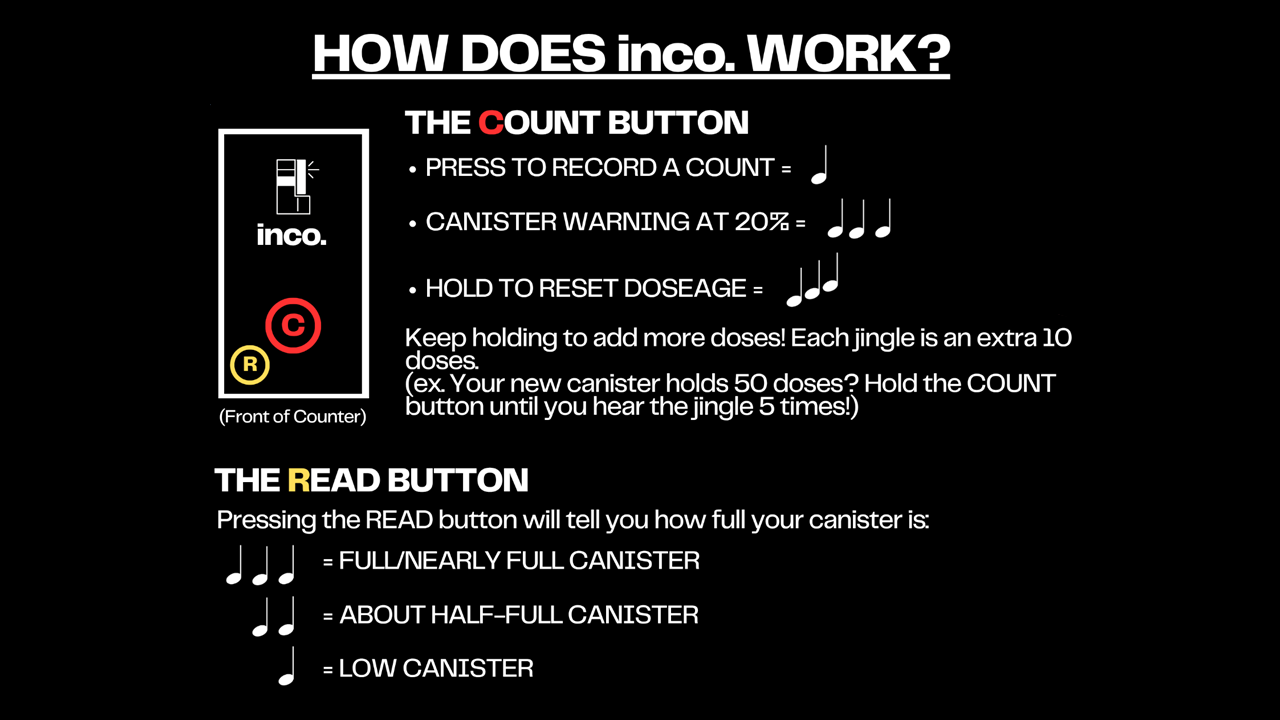

Hold the yellow button to start, and you’ll start to hear beeping. Each beep adds 10 doses to the computer's memory, and you keep adding doses until it matches the number of doses your new canister holds (for example, if your canister holds 50 doses, hold the yellow button until you hear five beeps). After filling, each press of the red button reduces the count after taking a puff. When the dosage drops below 20%, the counter vibrates, warning you that it’s time to refill.

We even textured the buttons differently so they’re distinguishable by touch: a raised bump marks the red button.

Figure 2: Early Prototype of Inhaler Counter (speaker, textured buttons, and buzzer yet to be included)

Figure 2: Early Prototype of Inhaler Counter (speaker, textured buttons, and buzzer yet to be included)

Figure 3: Inhaler Counter Infographic

Figure 3: Inhaler Counter Infographic

Design Considerations

The enclosure is compact and durable enough to fit in a pocket without interfering with normal inhaler usage. We avoided velcro because of the noise it makes, whixh is something we realized could be disruptive for users who are sound-sensitive. Instead, we went with a quiet, elastic strap that fits most inhalers. A thin protoboard made the whole circuit lightweight and compact. Another accessibility-related feature that we added was a vibration motor that accompanied the speaker in providing feedback to the user. This addition also allowed patients with auditory impairments to also use this device, which I thought was a brilliantly simple way to improve on the accessibility of our final product.

Next Steps and Conclusion

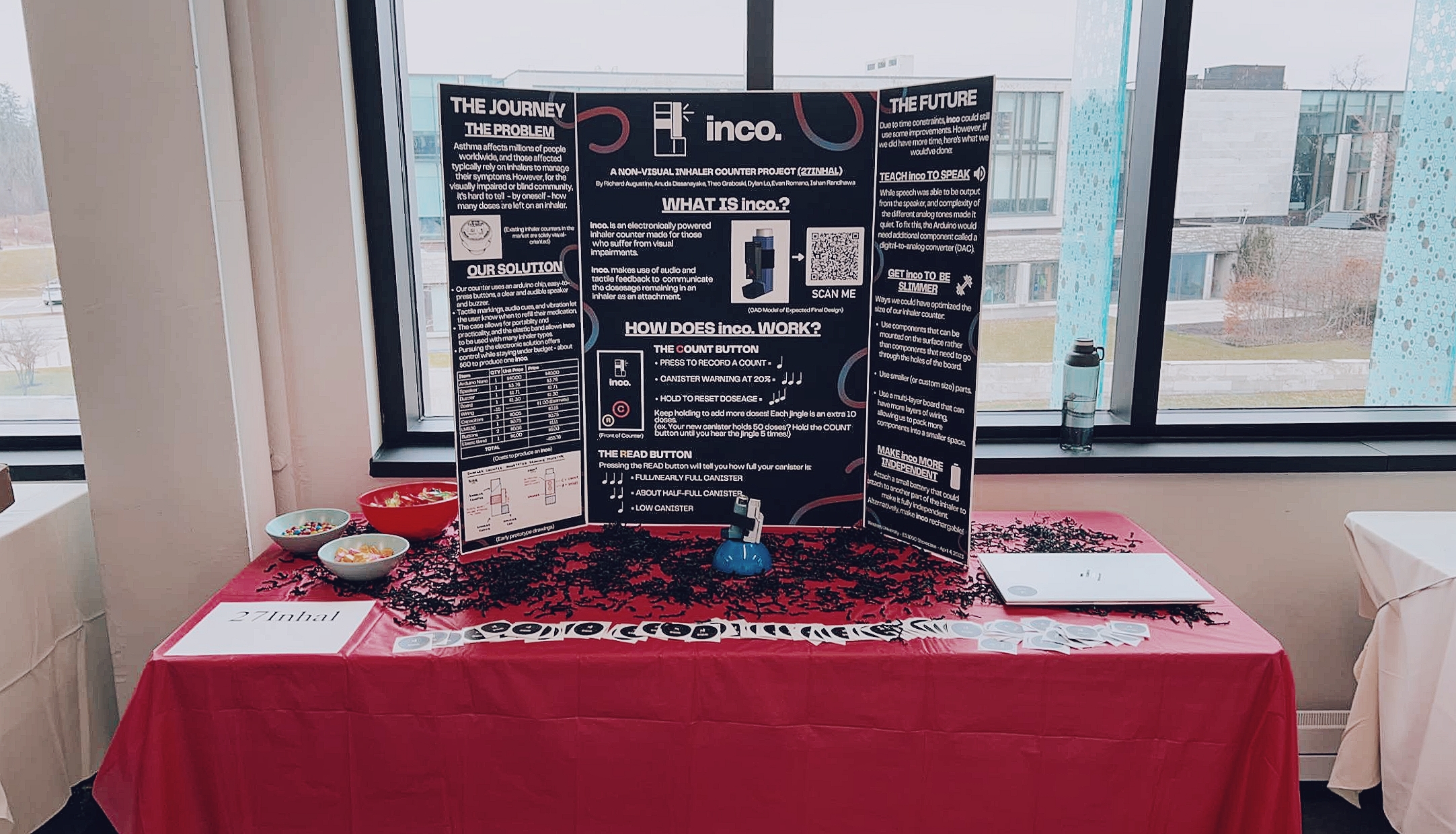

So, we achieved what we sought out to do. Current market options like the PuffMinder DOSER or the PUFFClicker offer visual readouts and app syncing, but they’re either not accessible to blind users or rely too heavily on smartphones. Ours doesn’t. It just works—with simple button presses and immediate, meaningful feedback. This project was submitted into a first-year engineering competition and won "Most Popular Project" out of 150 submissions, which I'm pretty proud of! In fact, I even designed a branding around our project and called it 'inco' (as in inhaler counter, you can clap now), which I produced stickers of to give away during the showcase :)

With more time, I’d also love to see:

- Voice feedback for more intuitive communication

- Rechargeable battery integration

- A logging system that tracks historical usage

- Better materials for durability, like a lightweight aluminum case

With these small upgrades, I can easily see this go from prototype to a fully deployable assistive tech product.

Overall, this was a great learning experience and the first engineering project I’ve worked on, and only the first of many. Details about this project, including the code and SolidWorks files, can be found on my GitHub! ^o^

Figure 4: Project Showcase at Engineering Competition

Figure 4: Project Showcase at Engineering Competition

Many Thanks to my Team: Evan R., Theo G., Anuda D., Ishan R., and Dylan L. 🎉